The Role of Engineering Consultancy in the Industrial Sector

Optimizing Production Processes and Improving Efficiency In today’s rapidly evolving industrial landscape, businesses must continuously improve their processes to maintain

Optimizing Production Processes and Improving Efficiency In today’s rapidly evolving industrial landscape, businesses must continuously improve their processes to maintain

Optimizing Production Processes and Improving Efficiency In today’s rapidly evolving industrial landscape, businesses must continuously improve their processes to maintain

Drones are transforming the engineering sector. Their versatility makes them ideal for inspections and surveys, providing precise and real-time data.

In the field of engineering, adhering to technical standards is crucial to ensure safe, efficient, and legally compliant projects. This

Upgrading existing buildings to meet new energy regulations is a key challenge in the journey toward sustainability. Recent national and

Plate heat exchangers are essential devices in various industries, including food processing, chemical production, and energy systems. Their modular design

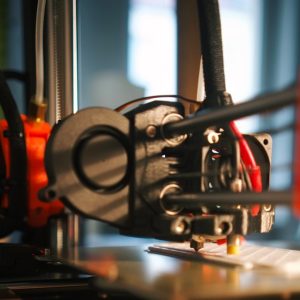

3D printing is revolutionizing the construction industry. In recent years, this technology has shifted from a futuristic concept to a